Production Machine

- Home

- Production Machine

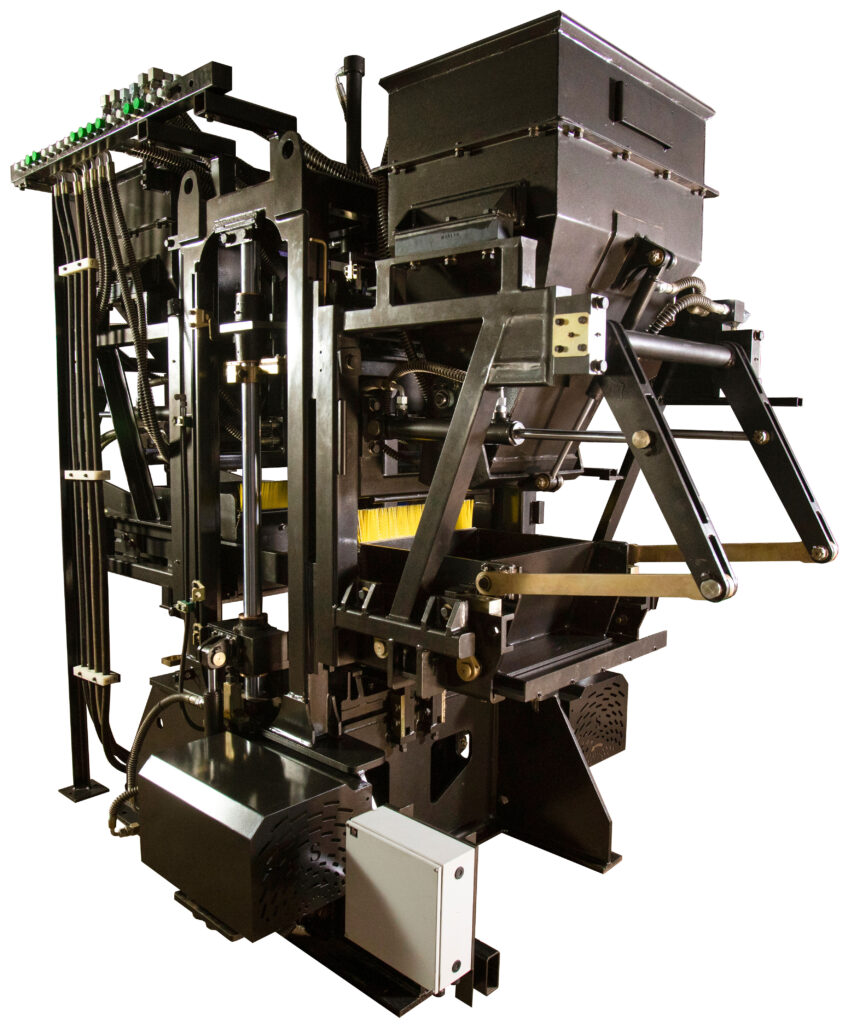

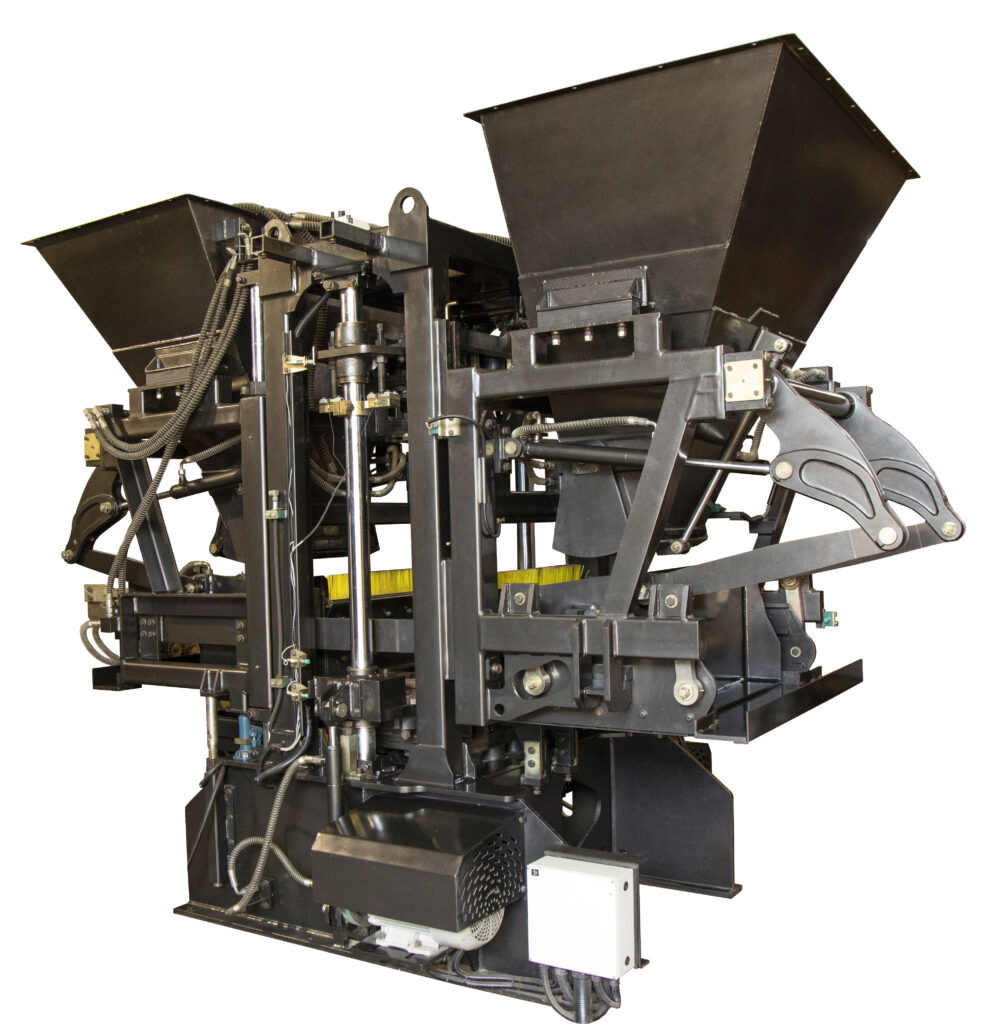

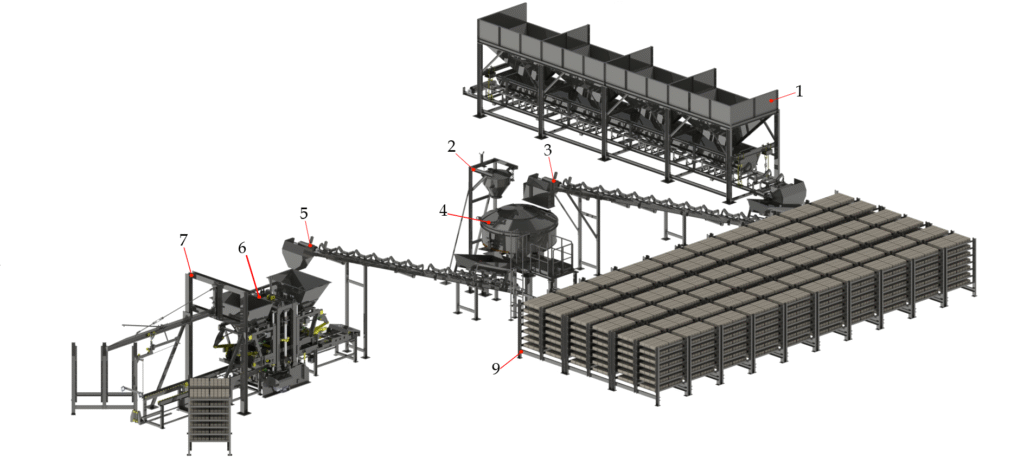

Metcon’s Model MN2S & MN3 are the most Efficient, Stationary, Fully Automated production machine capable of producing single or Multi-Layered concrete products. Sturdy structure along with cutting-edge electrical and hydraulics systems makes this machine highly reliable and most economical machine for production of very high-quality concrete products.

Technical Data

- Production Plate: 550x530x6 mm.

- Production Area: 500×480 mm.

- Production Height: 60 – 200 mm.

- Modern Electrical Control using Mitsubishi, Schneider Electric Controls & Systems

- Stone Height Control.

- Face Mix.

Model MN2S Concrete Block Plant Specifications

| Sl No | Description | Power (kW) |

|---|---|---|

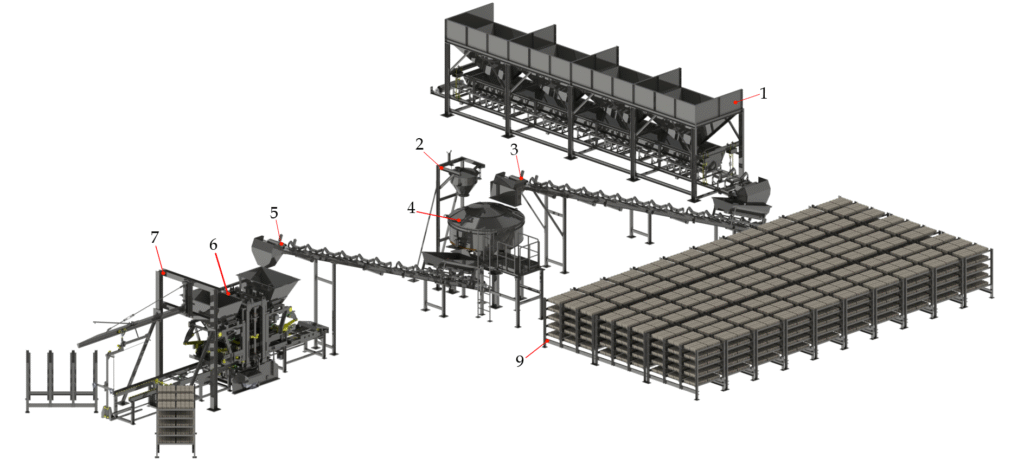

| 1 | 4/3/2 Nos. Aggregate Storage Bins — 5 cu.m. bin each for bulk storage of aggregate and sand material. | 4.5 |

| 2 | Automatic Cement Feeding and Batching System — Screw conveyor for feeding cement automatically from holding hooper or silo to cement weigh batcher. | 5.5 |

| 3 | Inclined Material Transfer Conveyor — Designed to convey aggregate and cement to mixer. | 4 |

| 4 | Pan Mixer Model Turbo 1000 — Designed to mix up aggregate and cement with output of 0.5 cu.m. concrete per batch. | 25 |

| 5 | Inclined Mud Belt Conveyor — Designed to feed concrete mix from mixer to MN2S machine. | 4 |

| 6 | Concrete Products Machine Model MN2S — Designed to produce concrete products on steel pallets of size 550x530x6mm. | 35 |

| 7 | Hydraulic Offbearer with Support Structure — Designed to pick up two pallets at a time for loading into curing racks. | – |

| 8 | Steel Production Pallet – 550x530x6mm — Designed to hold concrete product during production, curing and handling. | – |

| 9 | Steel Curing Racks — For storage of concrete products on pallet during curing process. | – |

Pallet Size: 550x530x6mm

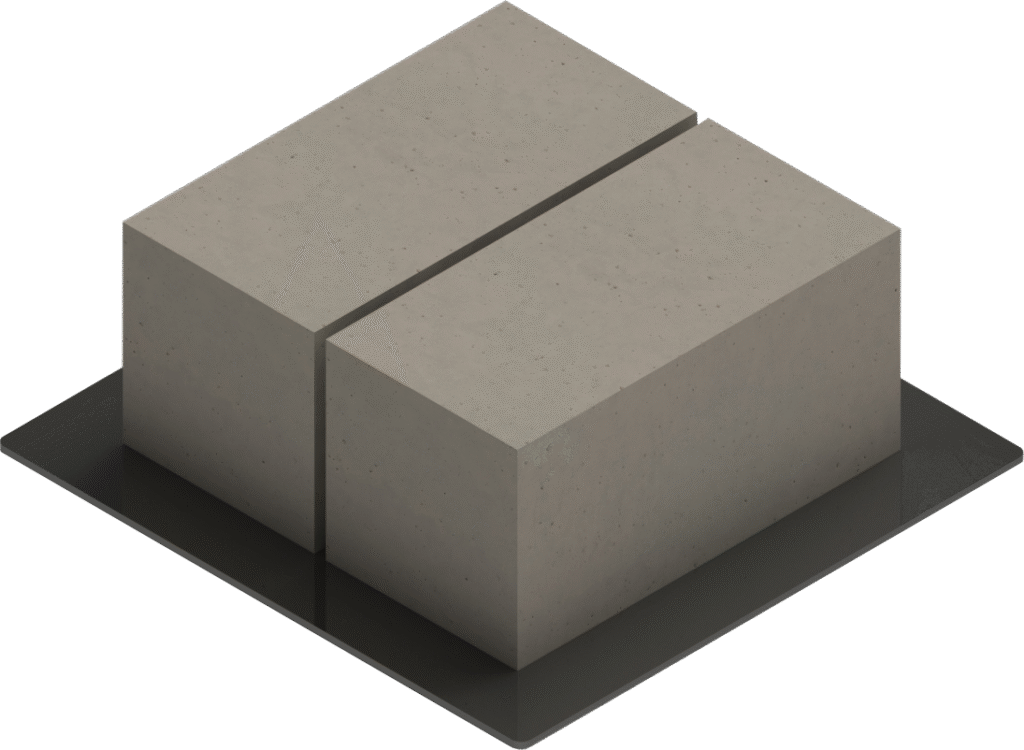

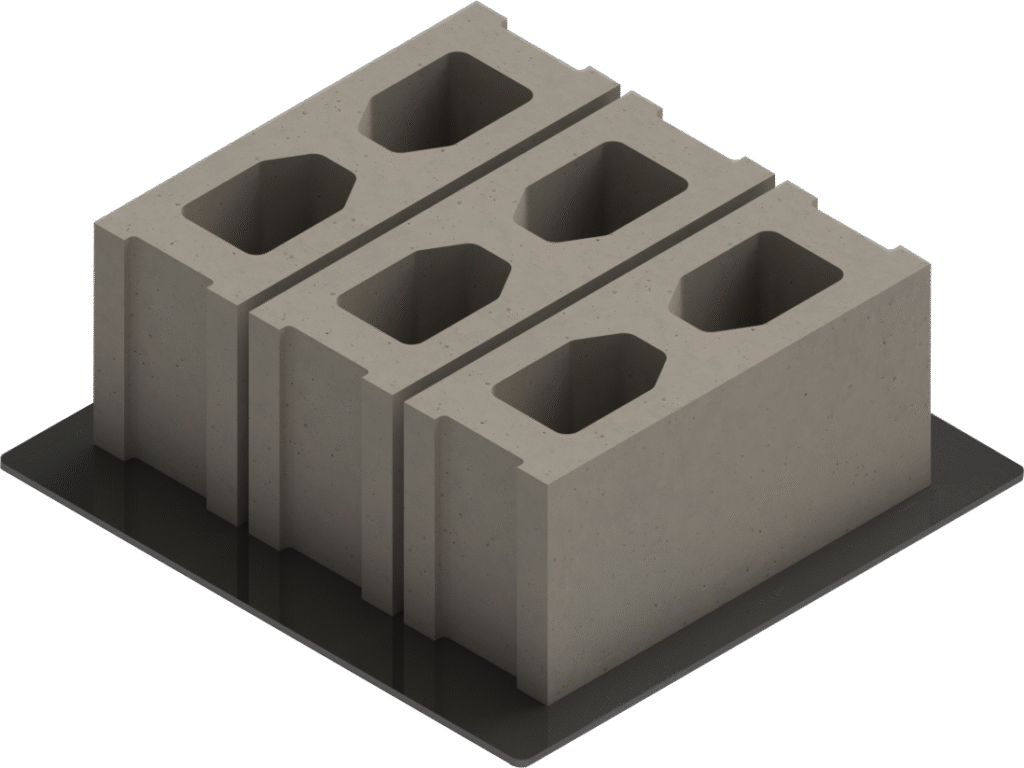

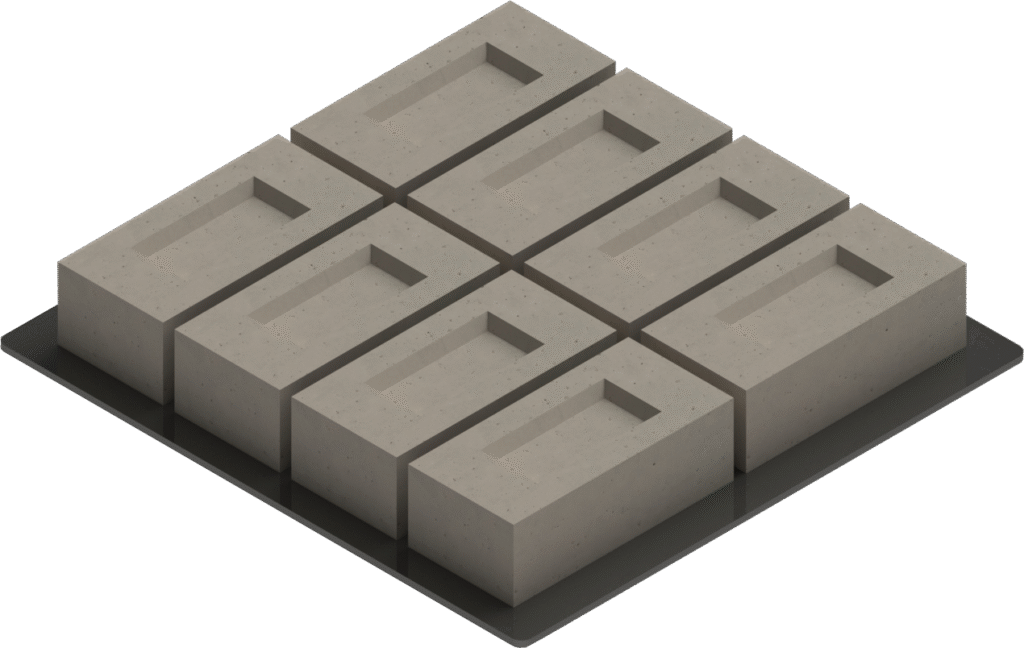

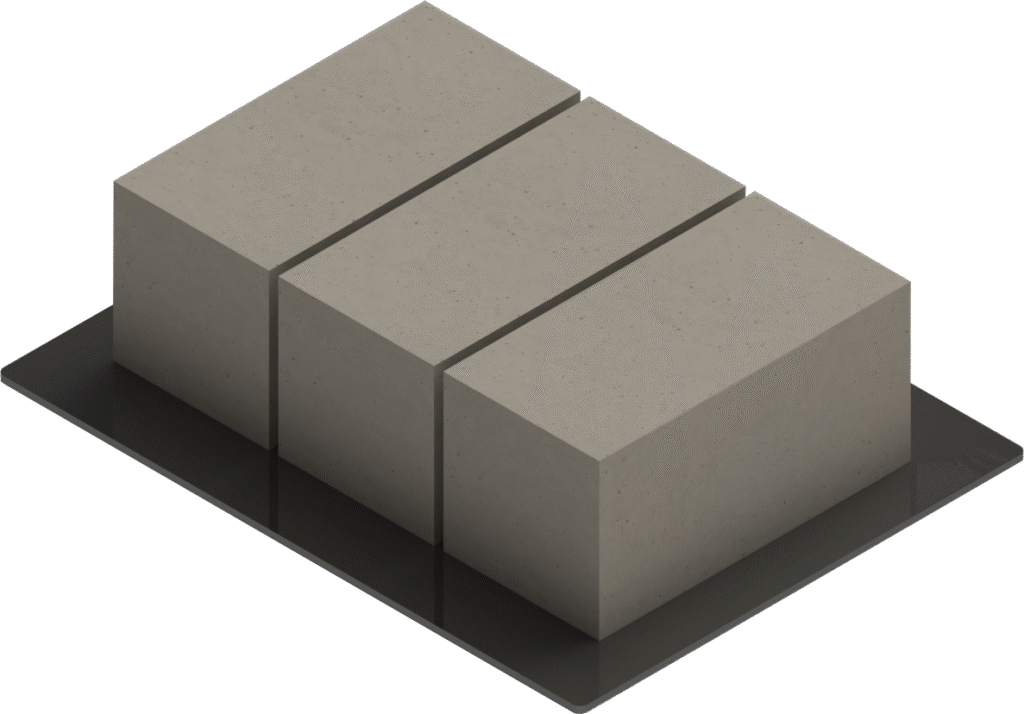

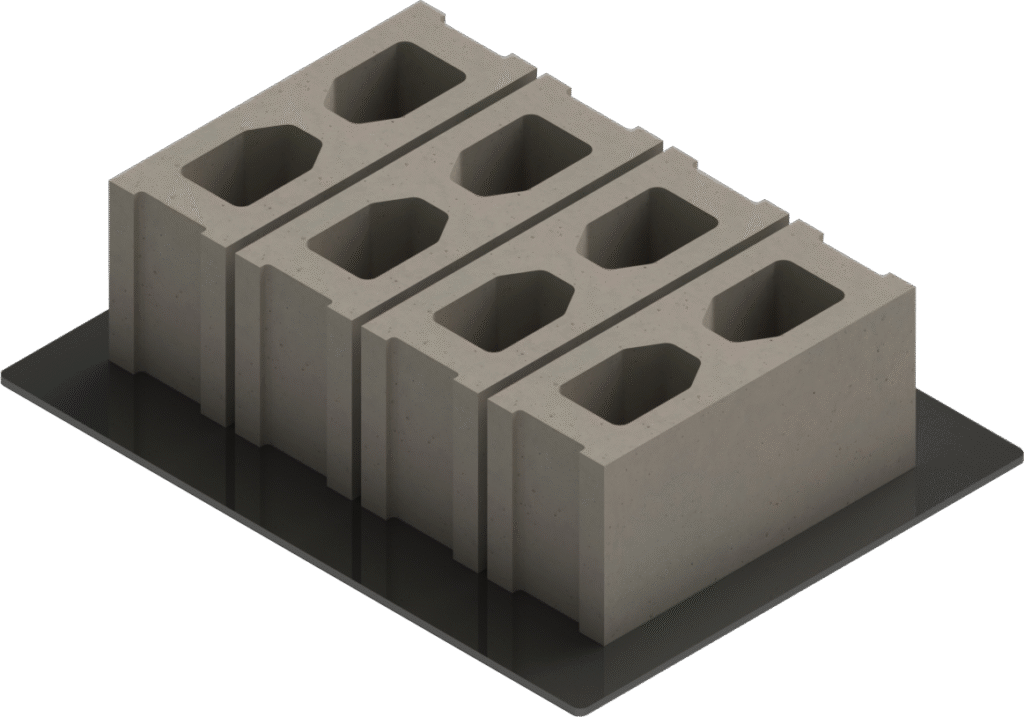

Hollow/ Solid Block

400x200x200mm (2) at a time

4,000 per 8 hours*

Hollow/ Solid Block

400x150x200mm (3) at a time

6,000 per 8 hours*

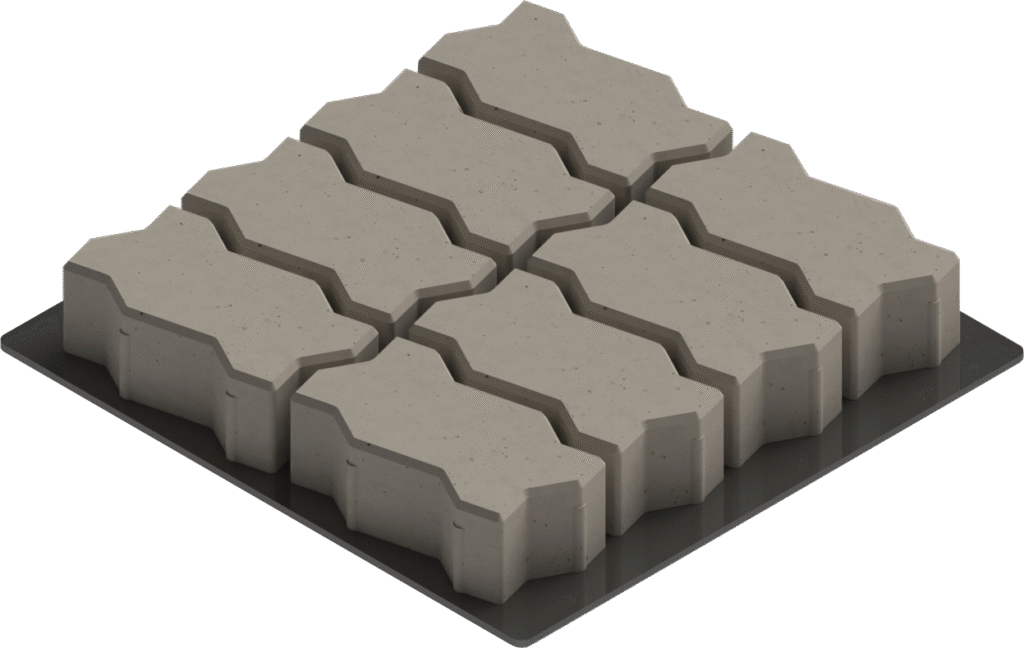

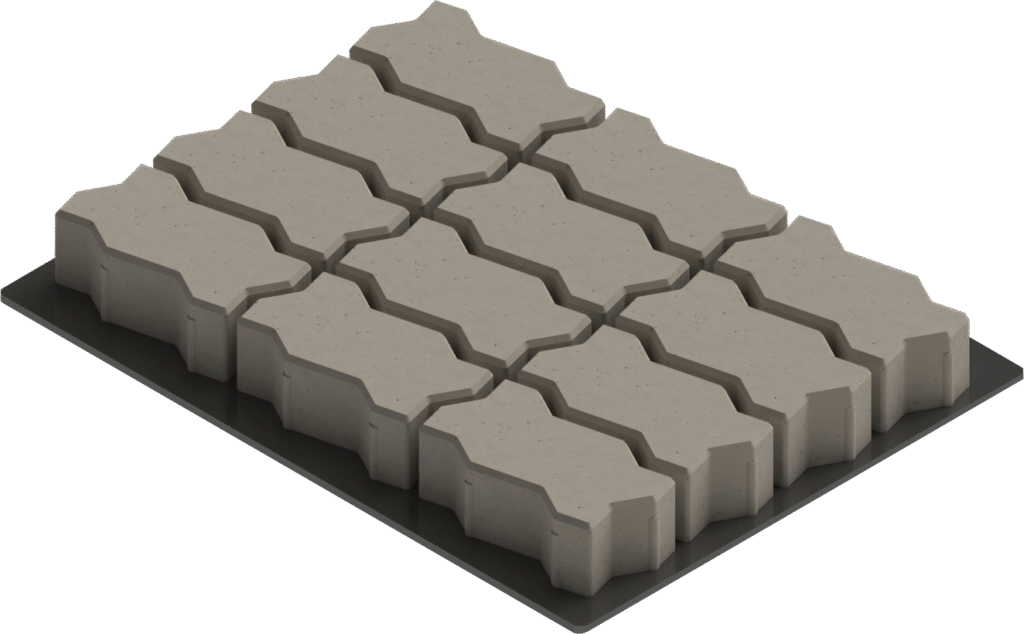

Unistone Paver

225×112.5x80mm (8) at a time

16,000 per 8 hours*

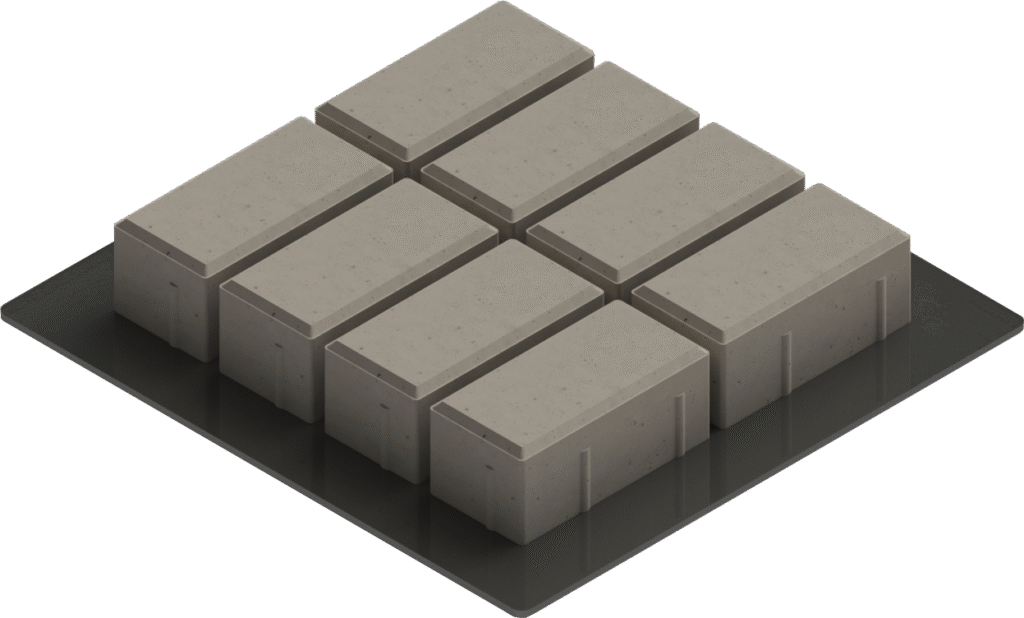

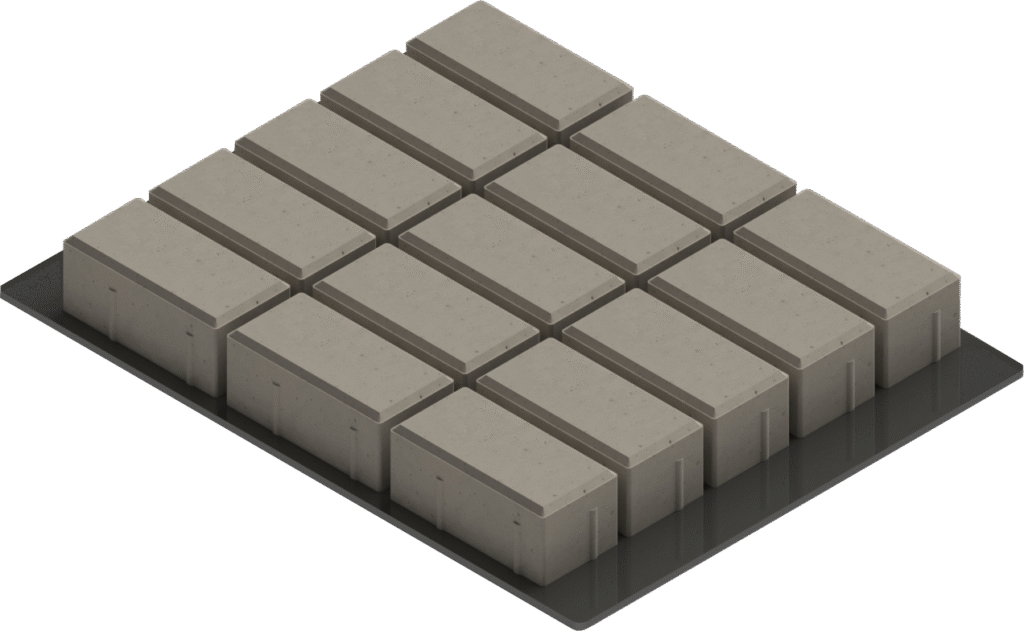

Rectangular Paver

200x100x80mm (8) at a time

16,000 per 8 hours*

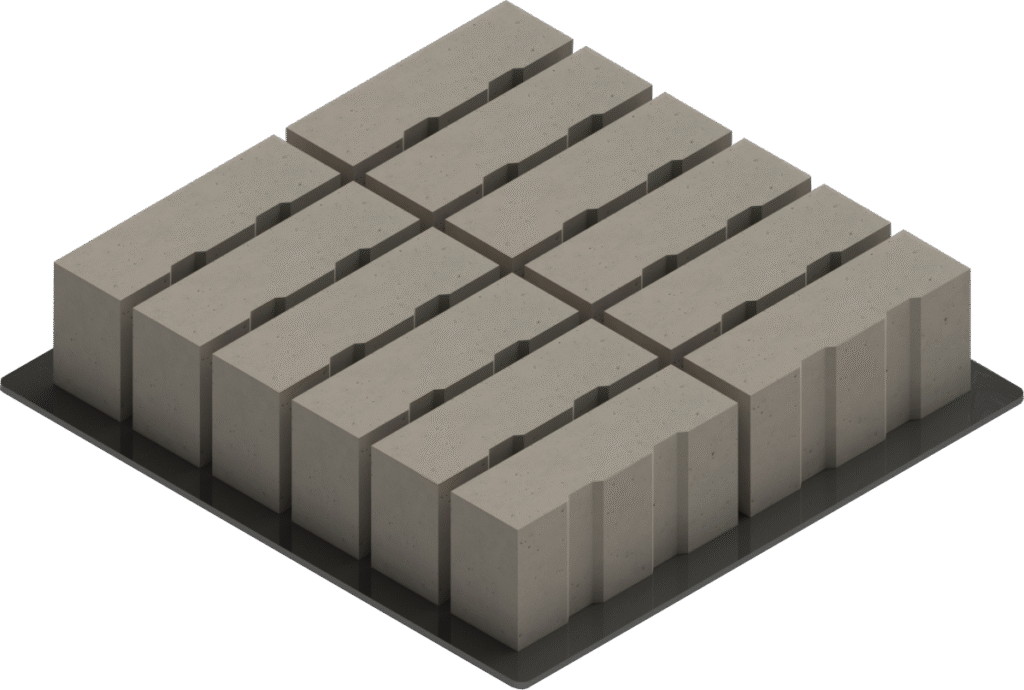

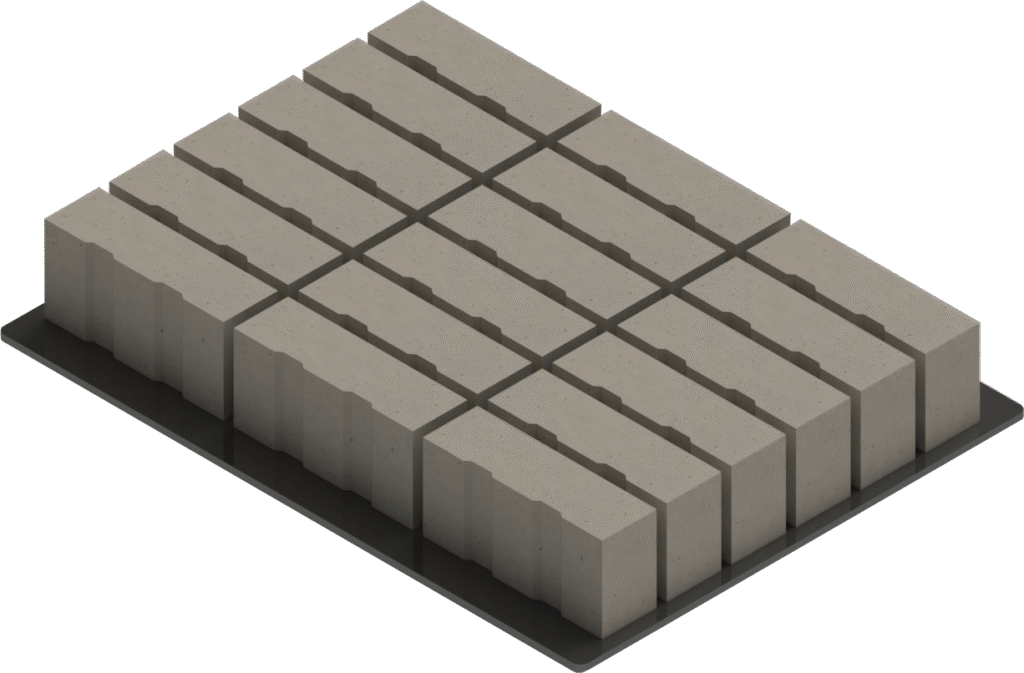

Flyash Brick (On Edge)

230x110x70mm (12) at a time

24,000 per 8 hours*

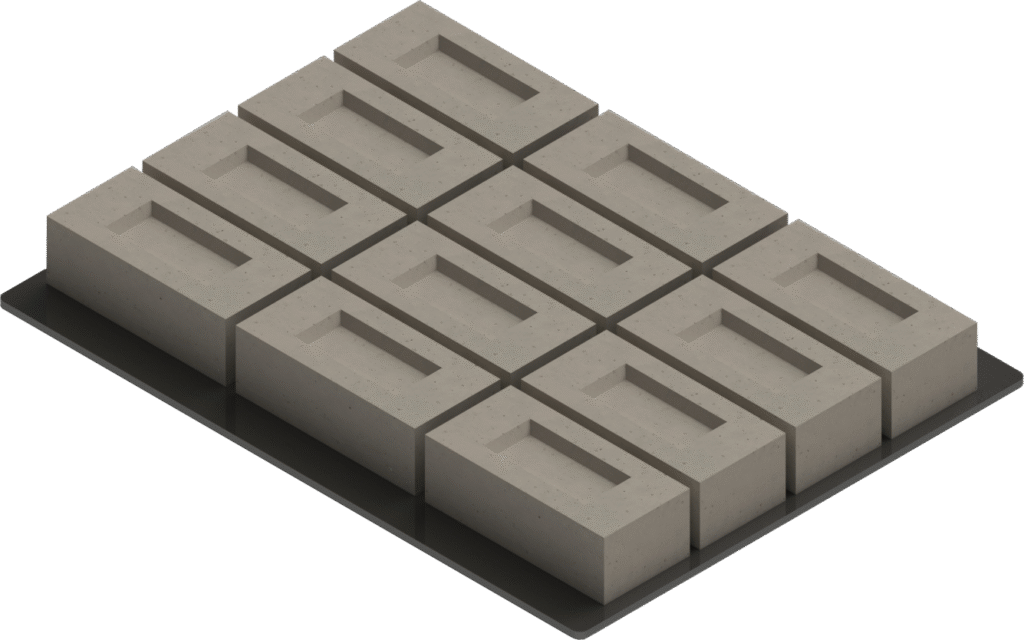

Flyash Brick (With Frog)

230x110x70mm (8) at a time

16,000 per 8 hours*

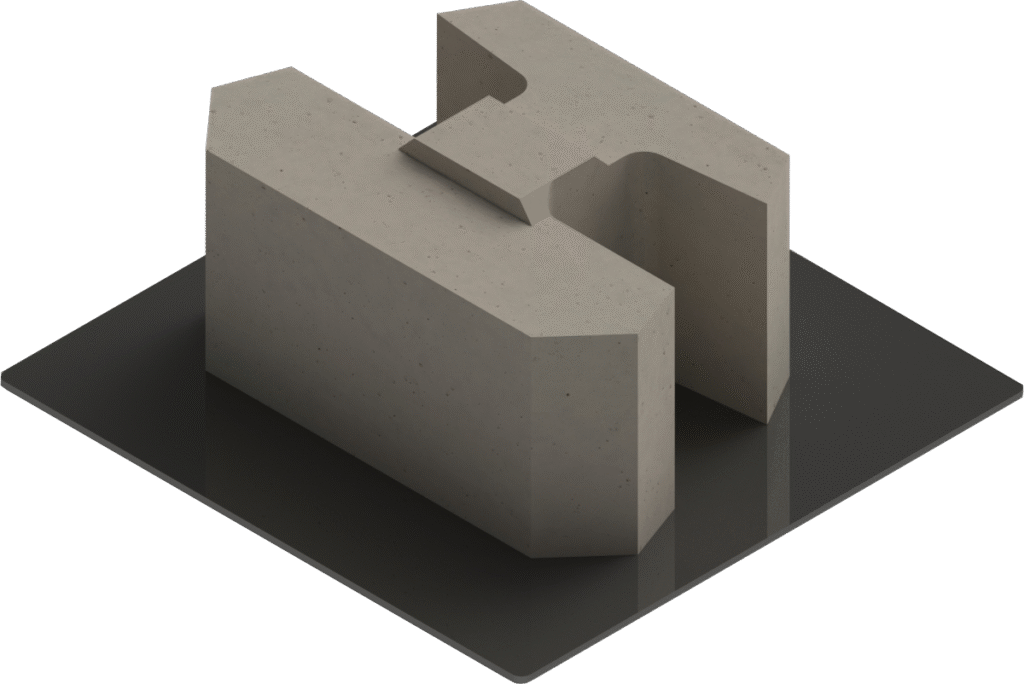

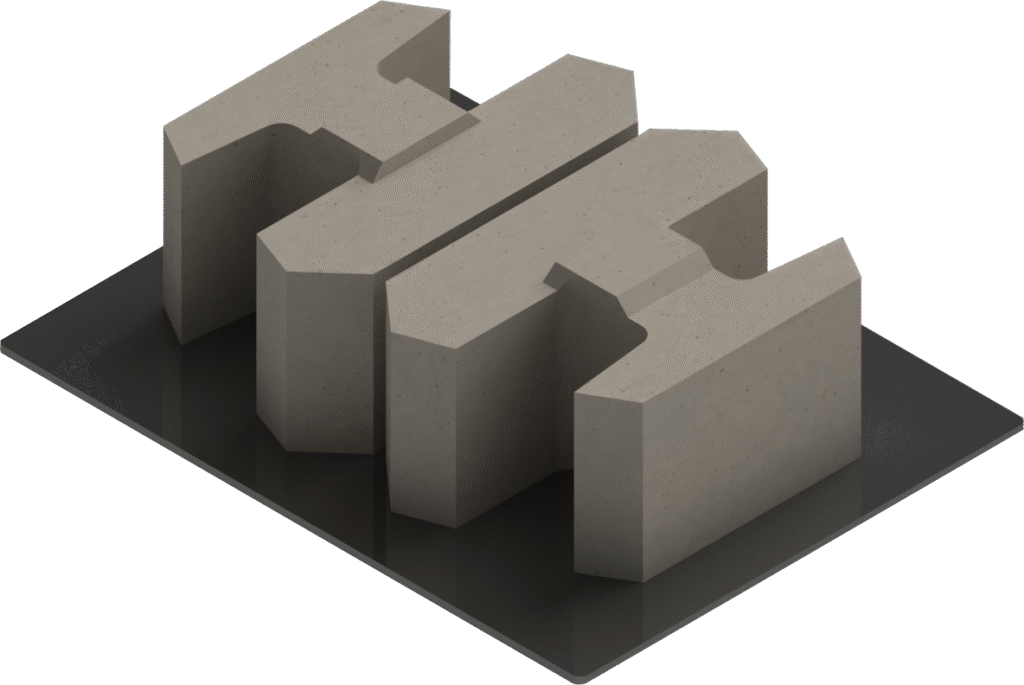

Retaining Wall Block

450x300x200mm (1) at a time

2,000 per 8 hours*

*@90% Production Efficiency & Single Layer Product

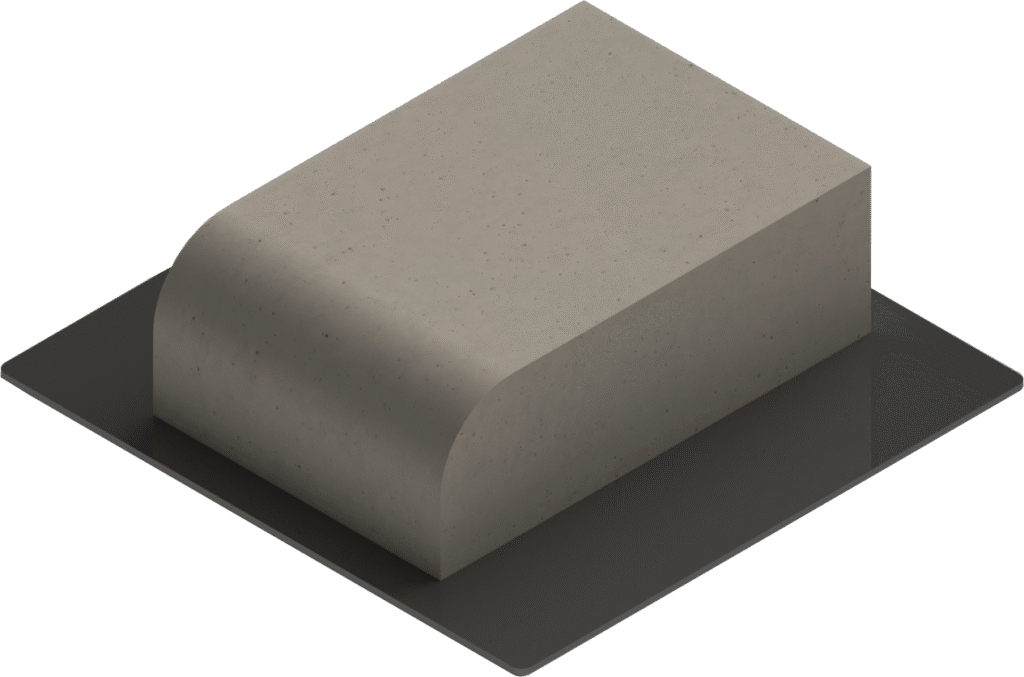

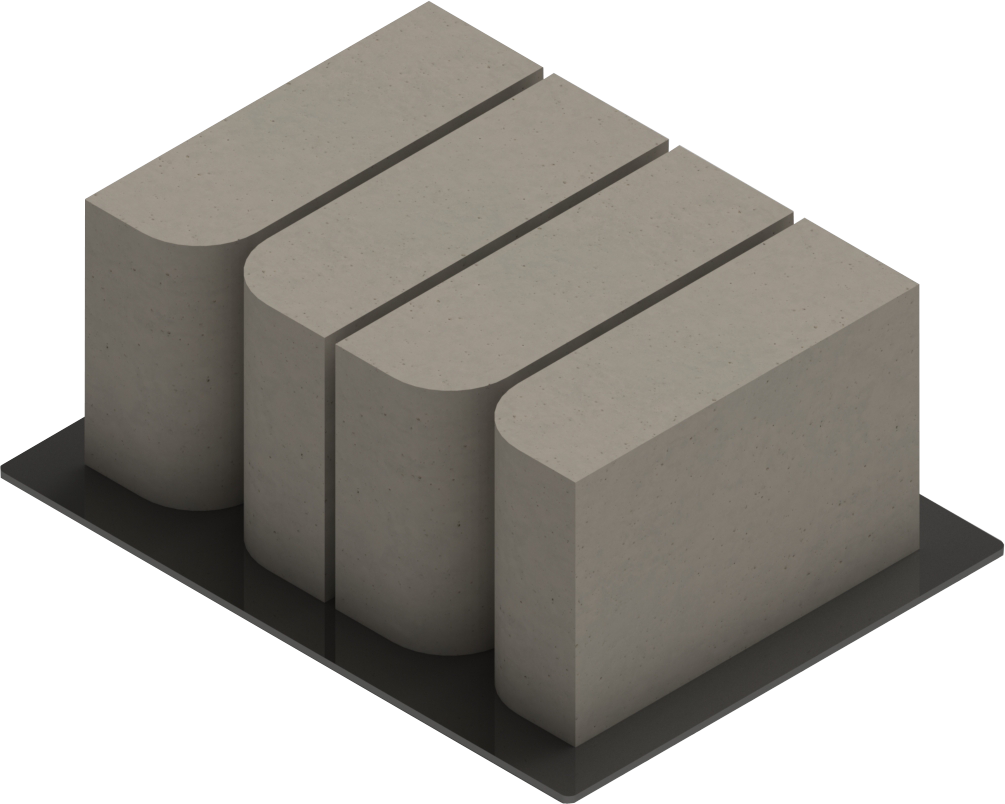

Kerbstone

450x150x300mm (1) at a time

2,000 per 8 hours*

Technical Data

- Production Plate: 750x575x8 mm.

- Production Area: 720×505 mm.

- Production Height: 60 – 300 mm.

- Modern Electrical Control using Mitsubishi, Schneider Electric Controls & Systems.

- Stone Height Control.

- Face Mix.

Model MN3 Concrete Block Plant Specifications

| Sl No | Description | Power (kW) |

|---|---|---|

| 1 | 4/3/2 Nos. Aggregate Storage Bins — 5 cu.m. bin each for bulk storage of aggregate and sand material. | 4.5 |

| 2 | Automatic Cement Feeding and Batching System — Screw conveyor for feeding cement automatically from holding hooper or silo to cement weigh batcher. | 5.5 |

| 3 | Inclined Material Transfer Conveyor — Designed to convey aggregate and cement to mixer. | 4 |

| 4 | Pan Mixer Model Turbo 1000 — Designed to mix up aggregate and cement with output of 0.5 cu.m. concrete per batch. | 25 |

| 5 | Inclined Mud Belt Conveyor — Designed to feed concrete mix from mixer to MN3 machine. | 4 |

| 6 | Concrete Products Machine Model MN3 — Designed to produce concrete products on steel pallets of size 750x575x8mm. | 40 |

| 7 | Hydraulic Offbearer with Support Structure — Designed to pick up two pallets at a time for loading into curing racks. | – |

| 8 | Steel Production Pallet – 750x575x8mm — Designed to hold concrete product during production, curing and handling. | – |

| 9 | Steel Curing Racks — For storage of concrete products on pallet during curing process. | – |

Pallet Size: 750x575x8mm

Hollow/ Solid Block

400x200x200mm (3) at a time

6,000 per 8 hours*

Hollow/ Solid Block

400x150x200mm (4) at a time

8,000 per 8 hours*

Unistone Paver

225×112.5x80mm (12) at a time

24,000 per 8 hours*

Rectangular Paver

200x100x80mm (15) at a time

30,000 per 8 hours*

Flyash Brick (On Edge)

230x110x70mm (18) at a time

36,000 per 8 hours*

Flyash Brick (With Frog)

230x110x70mm (12) at a time

24,000 per 8 hours*

Retaining Wall Block

450x300x200mm (2) at a time

4,000 per 8 hours*

*@90% Production Efficiency & Single Layer Product

Kerbstone

450x150x300mm (4) at a time

8,000 per 8 hours*